Tunable Diode Laser

Movie

Using the tunable laser. (youtube page)

Data Sheets

Lambda-Master 950

Lambda-Master 1040

High-Speed type (Max. rate: 600 nm/s) is available.

Product Summary

Our wavelength tunable lasers use our proprietary transposed Littman-type external resonator structure to completely separate the ASE from the output optical axis without sacrificing optical output intensity, achieving both high output intensity and high spectral purity (ASE-free). In addition, the Littman configuration, which is a geometrically and mathematically ideal configuration, is partially deformed to compensate for the dispersion of the LD chip and optics to achieve mode hop-free tuning over a wide wavelength bandwidth even in the 1um band, where chip dispersion becomes apparent, let alone in the communication band. To fully use the performance of the external cavity, a stepper motor type pressure contact slider with backlash-free and ultra-precise motion is used as the wavelength tuning actuator to achieve wavelength sweep performance that contributes to precision spectroscopic measurement. Other features include an analog wavelength sweep function using PZT, an auto-focus function for fiber couplings that takes advantage of high output power, and a data acquisition function synchronized to wavelength tuning, all of which can be fully utilized by the spectroscopic measurement software to meet the high demands of laboratory users. The software is available in executable file format, and LabVIEW source code is also distributed.

Key Features

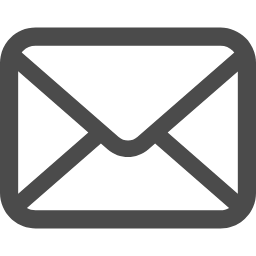

* Wavelengths from 880nm to 1680nm are available

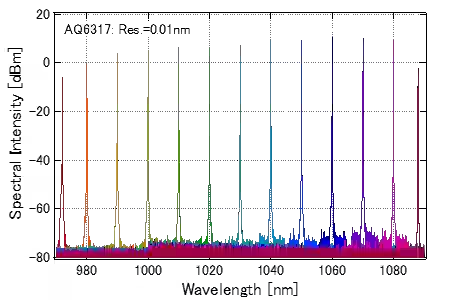

* ASE-Free Output : >80dB@0.01nm

* High Output Power : >100mW (Free), 50mW (Fiber)

* Wide Mode-Hop Free Tuning Range : >100nm

* Narrow Linewidth : ~100kHz (10 μs)

* Digital Control : 0.1pm /step res.

* Max Tunig Rate : 30nm/s, High-Speed type (600 nm/s) is available.

* Built-in Data Acquisition : 16bit – 2ch.

* PC Control : LabVIEW software

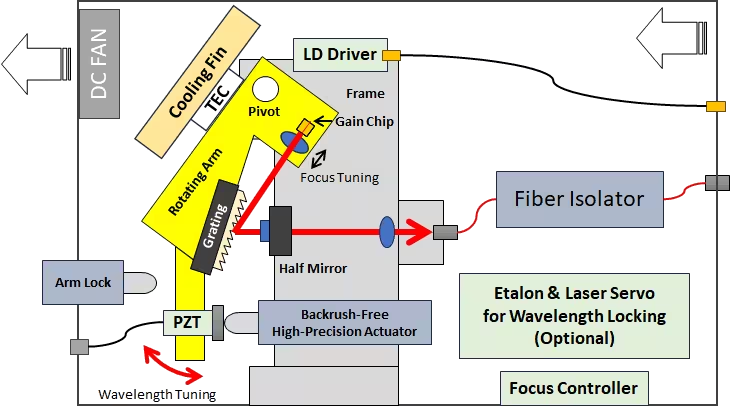

Schematic Diagram

Laser Head

In contrast to Littman configuration, cavity mirror is fixed and the unit composed of laser diode, collimation lens and grating is rotating around the pivot axis. First order diffraction light is taken out through the half mirror and coupled to a fiber. Chromatic dispersion of LD collimation lens is compensated with Focus adjuster. LD temperature is controlled by thermos-electric cooler and the heat is removed from the laser head with cooling fin and fan.

-Temperature Control-

Good heat dissipation is guaranteed when LD set temperature is higher than the ambient temperature. Setting LD temperature lower than ambient temperature (more than 2 centigrade) may cause heat over run. Once over heating happened temperature control will be automatically stopped. User should raise LD set temperature and restart the laser after sufficient cooling time (typically 30 min.)

-Wavelength Control-

Backlash-free, high precision actuator digitally controls the wavelength precisely with a unit of 0.1pm by tilting the arm around a pivot axis. PZT actuator on the arm additionally control the wavelength about 0.1nm (30GHz) by apply a voltage up to 150V.

-Fiber Coupling-

Fiber coupler is located inside the laser head and user cannot handle, except when coupling defect is apparent and SQL permits to access it. Fiber coupled beam is delivered to external fiber port through PM850 fiber with optical isolator. PM fiber with FC/APC connector should be connected to this fiber port. This unit equips focus adjuster to compensate chromatic dispersion. Focus adjuster is manually controlled by a front panel dial and also by a PC software. Auto focus in the application automatically tune the adjuster to the operating wavelength. When user use auto focus, manual control should be se zero position.

-Arm Lock-

Arm Lock on the laser head is only for the transportation. When laser is tuned to a longest wavelength limit, moving arm will be securely locked. So, user should not change this condition.

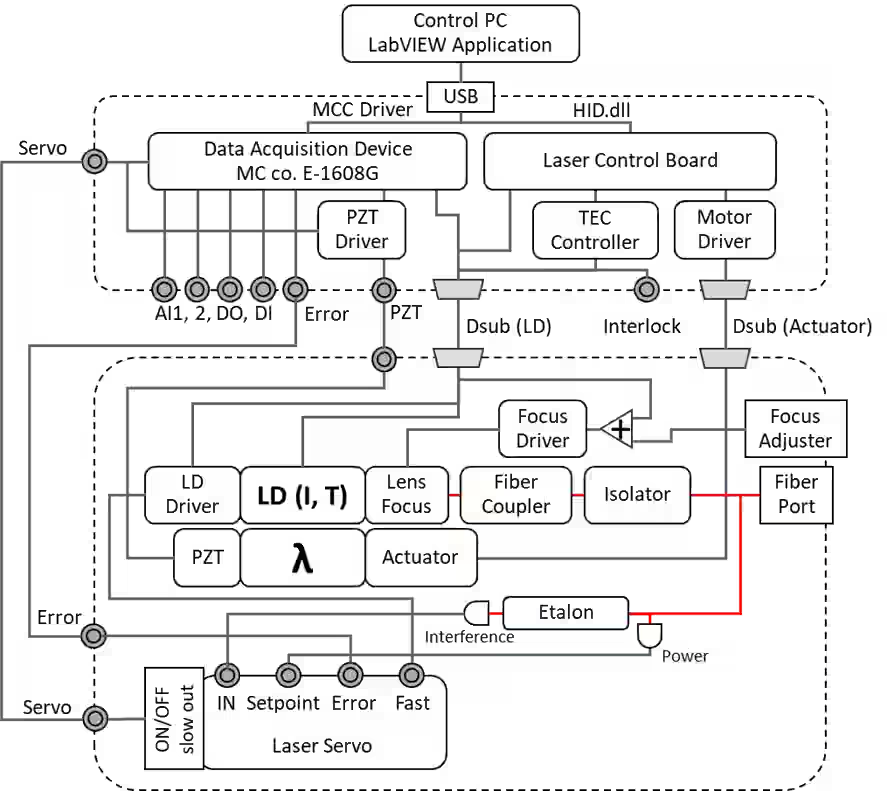

Controller

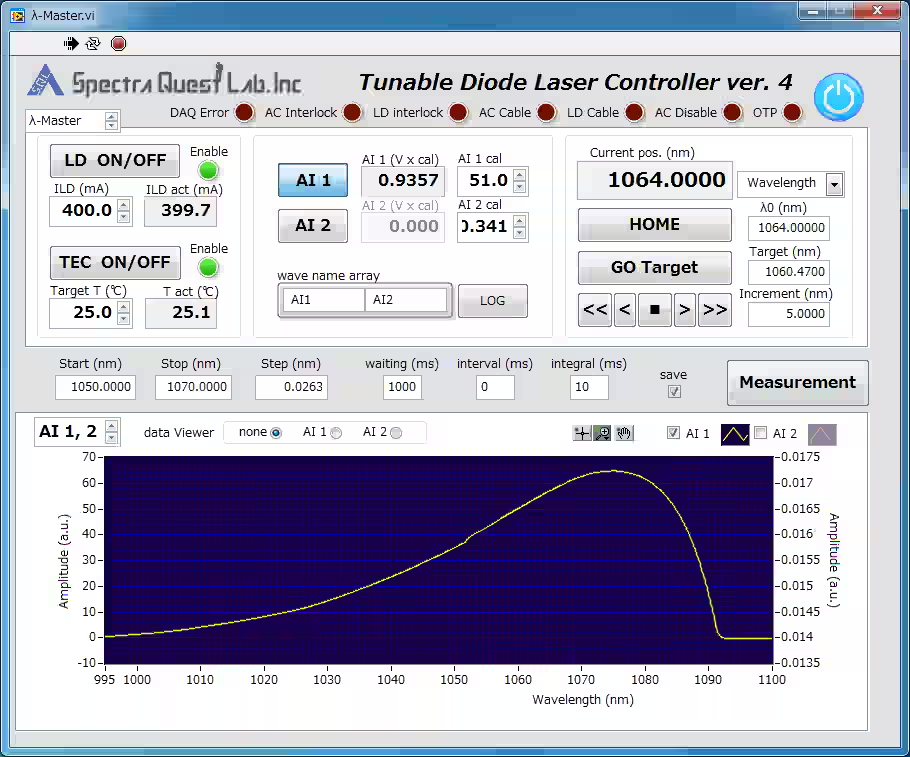

Controller is connected to PC (Window 11) with USB connector. Control is carried out via LabVIEW application software. LabVIEW source code and dll for device control are supplied to customers so customers can make personal control software.

-Current and Temperature Control-

LD current and temperature are controlled and monitored via AO, AI and DIO terminal of data acquisition unit (Measurement Computing Co. E-1608G). LD current modulation can be done through SMA terminal on the front panel of laser head.

-Wavelength Control-

High precision actuator for the wavelength tuning is controlled with our stepping motor motion controller. DI, DO terminal can be used to synchronize to external instrument in the step scan mode. Wavelength tuning (30GHz) by PZT actuator is carried out by applying a voltage (0-150V) to BNC terminal on the rear panel of laser head (Optional).

-Data Acquisition-

External signals can be acquired through AI-1 and AI-2 BNC terminals on the front panel of controller by 16-bit AD converters (+/-10V: Hi-Z), synchronized to wavelength scanning.

-Interlock-

Normally closed when laser is ON. Insert the supplied 3.5 mm stereo plug. If an emergency stop button is to be added, please use the button with the N.C. contact. PZT (PZT Option) Normally closed when laser is ON. Insert the supplied 3.5 mm stereo plug. If an emergency stop button is to be added, please use the button with the N.C. contact.

-Servo (Wavelength Lock Option)-

Normally closed when laser is ON. Insert the supplied 3.5 mm stereo plug. If an emergency stop button is to be added, please use the button with the N.C. contact.

Schematic Diagram

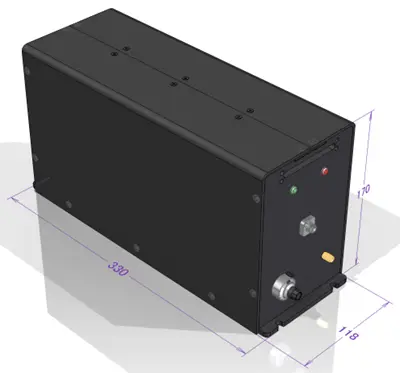

Laser Head

W118 x D330 x H170 (mm)

W118 x D330 x H170 (mm)

Controller

W250 x D300 x H66 (mm)

W250 x D300 x H66 (mm)

Related Data

ASE-Free Spectra

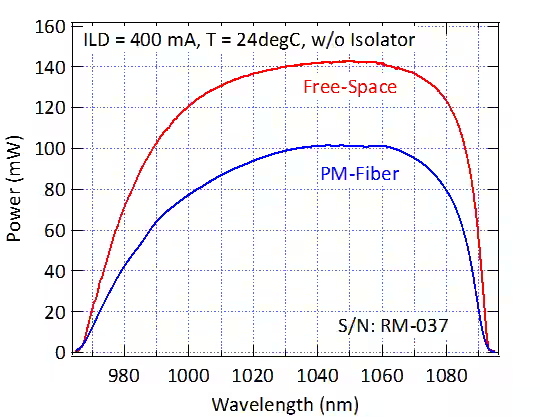

Free Space and Fiber Output

Control Software